A Complete Guide To Pressure-Treated Wooden Sheds

Table of Contents

- What is Pressure-Treated Wood?

- Pressure-Treated Wood Types

- Benefits of a Pressure-Treated Wooden Shed

- Things To Consider Before Buying A Pressure-Treated Wooden Shed

- Top 5 Pressure-Treated Wooden Sheds

- Alternatives Highlight: Autonomous WorkPods

- How To Install And Care For Your Pressure-Treated Wooden Shed

- FAQs

- Conclusion

When it comes to building a sturdy, reliable she shed for your backyard or garden, pressure-treated wooden sheds should be at the top of your list. Whether you're storing tools, equipment, or using it as a workspace, the material you choose plays a critical role in how long your shed will last. Pressure-treated wood is one of the best choices because of its ability to stand up to the elements, resist decay, and protect against pests.

Let’s dive into why this material is such a popular choice for homeowners and what to look for when investing in a pressure-treated wooden shed.

What is Pressure-Treated Wood?

A pressure-treated wooden shed is constructed using wood that has been infused with preservative chemicals to protect it from decay, pests, and moisture. This is done by placing the wood in a vacuum chamber, where pressure forces the chemicals into the fibers. The result is a wood that can withstand exposure to the elements much better than untreated wood.

Unlike untreated wood, which can quickly degrade, warp, or attract termites, pressure-treated wood for the shed floor and other components ensures long-term durability and strength. It’s a great option for structures exposed to constant moisture or humidity.

Pressure-Treated Wood Types

When selecting pressure-treated wood for your insulated she shed, it’s important to understand the different types available, as they are treated with varying levels of preservative chemicals based on their intended use.

Here are the main types of pressure-treated wood commonly used in shed construction:

1. CCA (Chromated Copper Arsenate) Treated Wood

CCA-treated wood was once the most common type used for outdoor projects, including sheds. It uses a combination of copper, chromium, and arsenic to protect the wood from decay, insects, and fungi.

However, due to the potential health risks associated with arsenic, it’s no longer widely used for residential purposes. Some older sheds may still contain CCA-treated wood, but modern alternatives are more commonly used now.

2. ACQ (Alkaline Copper Quaternary) Treated Wood

ACQ-treated wood is a popular choice for modern sheds. Unlike CCA, ACQ uses copper and a quaternary ammonium compound to treat the wood, making it safe for residential use, like a backyard guest house or a home office shed.

It’s highly effective against moisture, insects, and fungi, offering a long-lasting solution for shed construction. It’s also considered more environmentally friendly than older pressure-treated wood options.

3. CA (Copper Azole) Treated Wood

Copper azole is another popular treatment used for pressure-treated wood. It contains copper and an azole compound that is highly effective at preventing fungal decay and insect damage.

CA-treated wood is commonly used in residential and commercial outdoor projects, including she shed craft rooms, due to its proven effectiveness and safety for use in areas where children and pets may be present.

4. Micronized Copper Pressure-Treated Wood

Micronized copper pressure-treated wood is a newer treatment technology that uses finely ground copper particles to protect the wood. This type of treatment has several advantages, including a more natural appearance because it doesn’t have the bright green color typically associated with other types of treated wood. It also poses less environmental risk, as it doesn't contain the harsh chemicals found in older treatments.

5. Boron-Treated Wood

Boron is a naturally occurring element that is highly effective in preventing wood decay and insect infestations. Boron-treated wood is becoming more popular in areas with mild climates, as it’s highly effective against fungi, termites, and other pests. While it offers excellent protection in dry conditions, it’s not ideal for high-moisture environments, as boron can wash out over time.

Each type of pressure-treated wood offers unique benefits depending on your location and the specific needs of your shed. When building your shed, it’s important to choose the type that best suits the local climate and exposure conditions.

Benefits of a Pressure-Treated Wooden Shed

Pressure-treated wooden sheds are an excellent investment for any homeowner looking for durability, aesthetic appeal, and long-term value. The choice of using pressure-treated wood for the shed floor or pressure-treated plywood for the shed walls provides multiple advantages that make these sheds stand out from the rest.

- Long-Lasting Protection Against Moisture, Pests, and Mold

One of the biggest advantages of pressure-treated wood for the shed base or shed floor is its ability to resist moisture damage and pests. This makes it an ideal choice for a wood she shed that will stand up to rainy seasons or humid conditions.

For example, pressure-treated plywood for the shed floor can help prevent warping and mold growth that often plagues untreated wood.

- Cost-Effectiveness Over Time

Though pressure-treated wood may be more expensive upfront, the long-term savings are significant. Because this wood requires less maintenance and is more durable than untreated wood, you’ll spend less on repairs and replacements.

- Aesthetic Appeal

Pressure-treated wood for the shed walls and base can maintain a natural, rustic appearance that enhances the beauty of your backyard. Over time, it will weather to a silver-gray patina, which many people find appealing. You can also stain or paint it to match your style.

- Environmentally Friendly

Pressure-treated wood is not only a durable option, but it’s also an environmentally conscious one. It’s made from renewable resources and helps reduce the need for synthetic building materials that can harm the environment.

Things To Consider Before Buying A Pressure-Treated Wooden Shed

When planning to build a pressure-treated wooden shed, it’s important to consider several key factors that will influence its longevity, functionality, and cost. From the pressure-treated plywood for the shed floor to the materials used in the shed’s base, these details will ensure you get the best value from your investment.

- Size and Capacity

When selecting a pressure-treated wooden shed, it’s essential to choose the right she shed size for your storage needs. Do you need a small space for garden tools or a larger one for lawn equipment? The size will affect the cost and materials needed. Larger sheds will require more pressure-treated lumber for a shed base and floor, increasing the overall investment.

- Installation: DIY or Professional?

Installing a pressure-treated plywood shed floor or a completed shed can be a DIY project for those with the skills, but it may be worth hiring a professional for larger, more complex builds. Professionals can ensure that all aspects, from the pressure-treated lumber for the shed base to the roof, are installed correctly and securely.

- Maintenance

While pressure-treated wood is highly durable, it still requires some maintenance. Be sure to inspect your shed periodically for signs of damage, especially on the pressure-treated plywood for shed walls. Re-sealing the wood every few years will help extend its lifespan and keep it in top condition.

- Pricing

Pressure-treated wood for the shed floor or base may come at a premium, but it’s an investment in longevity. When evaluating your she shed prices, consider the long-term cost benefits—fewer repairs and replacements in the future will offset the initial cost.

Top 5 Pressure-Treated Wooden Sheds

Here are five top-rated pressure-treated wooden sheds for 2025, each offering a unique set of features designed to meet a variety of storage needs:

1. Tiger Elite Pressure-Treated Apex Shed

The Pressure-Treated Apex Shed is a top-tier option for anyone needing a reliable storage solution. Constructed with pressure-treated wood for the shed floor and walls, this shed provides excellent protection against moisture and pests. Its spacious interior allows for the storage of larger items such as gardening tools, equipment.

This pressure-treated wooden shed can even be used as a workshop or a backyard art studio for creative projects. It is designed to withstand the harshest weather conditions, making it an ideal choice for those seeking a durable and versatile structure.

2. Heartland Madison Shed with Windows

The Madison Shed combines durability with style, featuring pressure-treated plywood for shed walls and large windows that provide plenty of natural light. This makes it an excellent choice for those looking to turn their shed into a small she shed.

The pressure-treated construction ensures that the shed remains resistant to the elements, ensuring longevity even in damp or humid climates. The windows not only improve the aesthetic appeal but also make the shed feel more spacious and welcoming.

3. Aceshed The Ascot

The Ascot is a practical and sturdy shed built with pressure-treated wood for the shed base and floor. This shed is designed for easy assembly, making it a great option for DIY enthusiasts. Its modern look fits well in most backyards, providing a reliable space for storing tools and outdoor equipment.

The Ascot shed offers excellent weather resistance, making it a solid choice for regions with varied climates. Its compact size makes it ideal for smaller storage needs.

4. Handy Home Scarsdale Wood Storage Shed

This wooden storage shed is a budget-friendly solution for homeowners seeking additional storage space. Built with pressure-treated plywood for the shed floor, this structure offers a durable and weather-resistant foundation perfect for outdoor storage.

While it has a more basic design compared to higher-end studio sheds, the Scarsdale shed still provides all the essentials needed to keep your tools and equipment safe from the elements. It’s an excellent choice for those looking for a functional shed without breaking the bank.

5. Powersheds Premium Apex Shed

The Apex Shed is a larger, premium option built with high-quality pressure-treated lumber for a shed base. Known for its robust construction, this shed is designed to handle heavy-duty storage needs, such as larger equipment and lawnmowers. Its spacious interior and sturdy build ensure that your items are well-protected from the elements.

The premium materials used in the shed’s construction, including pressure-treated wood, guarantee longevity and resistance to moisture, making it a smart choice for those with significant storage requirements.

These five pressure-treated wooden sheds offer a variety of features suited to different needs, whether you're looking for a small storage space or a larger, more versatile structure. All are constructed with durable, pressure-treated wood, ensuring that they provide long-lasting protection and withstand the elements year after year.

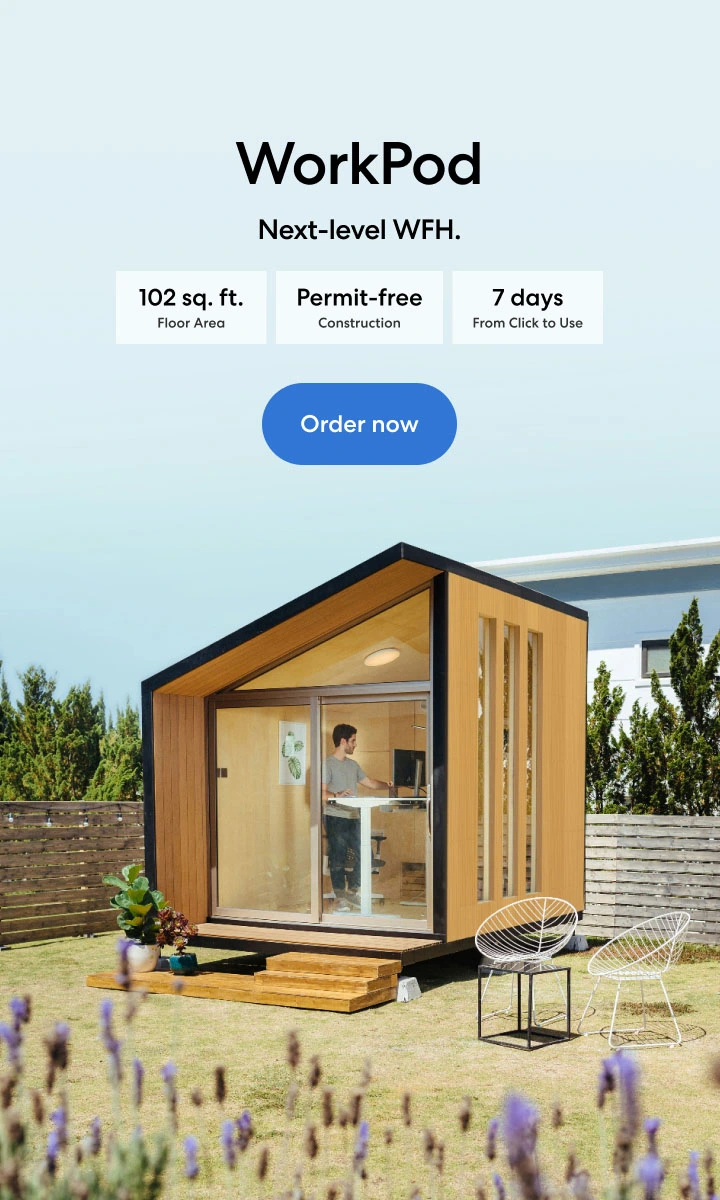

Alternatives Highlight: Autonomous WorkPods

If you’re considering alternatives to traditional pressure-treated wooden sheds for your outdoor storage or workspace, Autonomous WorkPods offer an innovative and modern solution. Designed with flexibility and durability in mind, the Autonomous WorkPods can serve as an excellent alternative for those looking for a more advanced, customizable, and versatile outdoor structure. Here's a look at three standout models:

- Autonomous WorkPod

The Autonomous WorkPod is a sleek, compact structure designed to function as a private she shed office, garden studio, or even a quiet man cave shed in your backyard. Unlike a traditional pressure-treated wooden shed, the WorkPod is built with modern, high-performance materials that provide excellent insulation and soundproofing, making it perfect for work, study, or relaxation.

With its fully enclosed design, the Autonomous WorkPod offers year-round protection from the elements without the hassle of regular maintenance that comes with wooden sheds.

- Autonomous WorkPod Versatile

The Autonomous WorkPod Versatile is designed for users who need more space and flexibility. Whether you're creating an outdoor home office, a creative studio, or a multipurpose storage unit, this she shed with windows adapts to various needs.

Its modular design allows for easy customization with ergonomic furniture and other accessories, creating a comfortable and functional space. The pressure-treated wood for the shed base and other components found in traditional sheds is replaced with cutting-edge materials in the WorkPod Versatile, offering a more modern and low-maintenance solution.

- Autonomous WorkPod Mini

For those with more limited space but still in need of a durable, insulated structure, the Autonomous WorkPod Mini is an ideal choice. Compact yet highly functional, the Mini version maintains all the benefits of the larger WorkPod models, such as weather resistance and insulation, while taking up less room in your backyard.

It’s perfect for small offices, remote workspaces, or even as a private she shed library. The Autonomous WorkPod Mini eliminates the need for constant upkeep and provides a sleek, modern alternative to a pressure-treated wooden shed.

How To Install And Care For Your Pressure-Treated Wooden Shed

Building and maintaining a pressure-treated wooden shed requires careful planning and attention to detail. Whether you're opting for pressure-treated plywood for the shed floor or pressure-treated wood for the shed base, here’s a step-by-step guide to ensure your shed remains durable and functional for years to come.

- Site Preparation

Start by preparing a flat, level area for your shed. It’s important to ensure proper drainage to prevent moisture from accumulating around your pressure-treated wood for the shed base.

- Base Installation

Begin by laying a strong foundation using pressure-treated lumber for a shed base. Ensure that all wood pieces are level and secured tightly to prevent shifting over time.

- Shed Assembly

Once the base is ready, start assembling the walls, flooring, and roof using pressure-treated plywood for the shed floor and pressure-treated wood for the shed walls. Always use galvanized or stainless steel fasteners to prevent rust.

- Sealing and Maintenance

After assembly, apply a weatherproof sealant to your shed to protect the wood from moisture. Make sure to inspect it regularly for signs of damage and reseal every couple of years.

FAQs

1. Is it worth getting a pressure-treated shed?

Yes, a pressure-treated wooden shed is worth the investment. It offers long-lasting protection against moisture, pests, and decay, which makes it ideal for outdoor use. While the upfront cost may be higher, the durability and reduced maintenance costs over time make it a smart choice for long-term use.

2. How long will a pressure-treated shed last?

A pressure-treated shed can last anywhere from 15 to 30 years, depending on the quality of the wood, climate conditions, and maintenance. Regular care and sealing can extend its lifespan, ensuring it remains durable and functional for decades.

3. What are the disadvantages of pressure-treated wood?

The main disadvantages of pressure-treated wood are its higher initial cost and the need for occasional maintenance, such as re-sealing. Additionally, the wood may have a greenish tint due to the chemicals used, though this can fade over time. It's also heavier than untreated wood, which can make installation more challenging.

4. Do sheds need to be pressure-treated?

While not every shed requires pressure-treated wood, it's highly recommended for outdoor structures that will be exposed to the elements. Pressure-treated wood for the shed floor and base helps prevent decay, moisture damage, and pest infestations, making it a more durable and long-lasting option.

5. Should you use pressure-treated wood for the shed floor?

Yes, it’s a good idea to use pressure-treated wood for the shed floor. This type of wood offers excellent resistance to moisture, rot, and pests, which is essential for the shed’s floor that is frequently exposed to damp ground. Using pressure-treated wood ensures a longer-lasting, stronger foundation for your shed.

6. What type of wood is best for a shed?

The best type of wood for a shed is pressure-treated lumber, as it provides enhanced durability and resistance to moisture, decay, and pests. For the shed floor, pressure-treated plywood is also a great option. If you're looking for a more cost-effective solution, cedar or redwood can be good alternatives for smaller, less exposed sheds.

Conclusion

A pressure-treated wooden shed is a smart, long-lasting investment for anyone looking to improve their outdoor storage solutions. With the right materials—whether it’s pressure-treated plywood for shed walls or pressure-treated lumber for the shed base—you’ll ensure that your shed is strong, durable, and resistant to the elements. Whether you’re building a shed from scratch or upgrading your existing structure, pressure-treated wood is the key to achieving a long-lasting, low-maintenance solution.

If you're considering using your shed as a more personal space, there are plenty of she shed interior ideas to transform it into the perfect retreat. You might also be interested in woman cave ideas, which offer inspiration for turning your shed into a relaxing, functional space tailored to your needs.

Ready to build your dream shed? Consider these top picks for 2025 and take the first step toward a durable, eco-friendly backyard addition.

Spread the word

.svg)

.webp)

.webp)