Prefabricated Building Construction: What Is It, and How Is It Made?

Table of Contents

- What Is a Prefabricated Building?

- How Is a Prefab Building Made?

- Applications of Prefabricated Buildings

- The Best States for Building Prefab Structures

- A Detailed Overview of the Benefits of Prefabricated Buildings

- The Potential Risks and Challenges of Prefabricated Construction

- The Seven Different Types of Prefabricated Structures

- How to Decorate a Prefabricated Building Unit without Breaking the Bank?

- Final Words

If you've been thinking about different housing choices, you might have heard about "prefabricated building construction." Also known as a home pod in many places, such units are gaining attention throughout the US.

What exactly is a prefabricated building, and how is it made? In this complete guide, we'll unravel the mysteries of prefabricated structures. Sit tight as we explore their various applications.

What Is a Prefabricated Building?

Businesses make prefabricated buildings off-site. Companies produce it in a controlled environment. They later transport it to its final location for assembly. This method differs from traditional on-site buildings, where parts are made entirely on-site.

You can customize prefab structures to suit various needs. This makes them ideal for different applications, from residential homes to commercial spaces. The beauty of a prefab accessory dwelling unit (ADU) is in its efficiency and versatility.

How Is a Prefab Building Made?

Now that you know what a prefab backyard workroom is, let's take a closer look at how companies make it. The construction process of such a unit involves several steps:

1. Design and Planning

The journey of a prefabricated building begins with design and planning. Architects and engineers unite to create detailed blueprints. They select materials that they'll use in the fabrication process.

2. Fabrication

The key advantage of prefabricated construction is that it happens in a controlled factory setting.

Businesses make components, such as walls, floors, and roofing, in a controlled environment. This allows for accuracy and quality control. The process can involve various materials, from wood and steel to concrete and glass.

3. Transportation

Once the individual pieces are ready, workers transport them to the construction site. This can be an advantage, especially in challenging weather conditions. It reduces exposure to the elements.

Companies transport such units using trucks, trailers, or shipping containers for long-distance projects.

4. Assembly

On-site assembly of prefabricated structures is faster than traditional construction. Manufacturers assemble the components according to the pre-designed plans. The focus is on accuracy and efficiency. Skilled workers use bolts, screws, and welding techniques to ensure secure connections.

5. Customization

Prefab structures are customizable. Whether you're looking to create a prefab studio on your property or a functional backyard pod, you can tailor the design to meet your specific needs and preferences.

Applications of Prefabricated Buildings

Prefab buildings come in various shapes and sizes, each serving a different purpose. Here are some popular types of prefabricated structures:

Prefab Accessory Dwelling Units (ADUs)

These small living spaces are great for homeowners who want to expand their living areas without costly renovations.

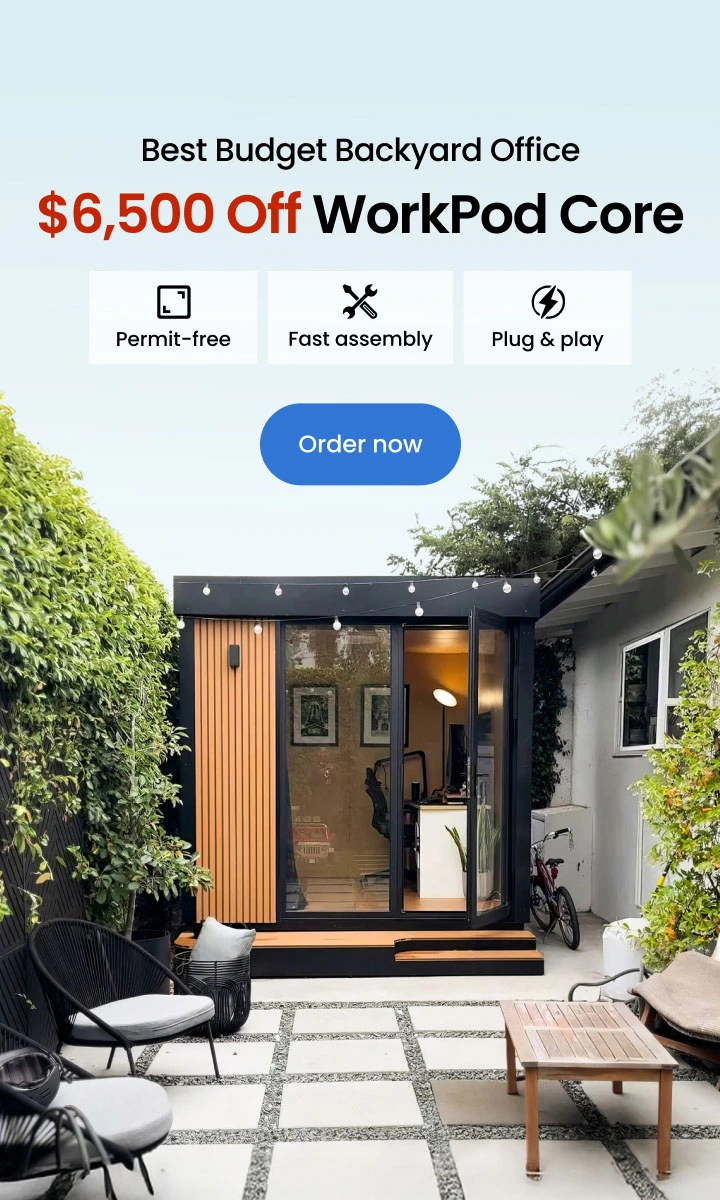

External Pods

Such pods are a modern take on modular housing. They offer versatility and can serve as guest rooms, home offices, or even mini studios. Use your new prefab ADU in Oregon as an Airbnb to earn as well.

Backyard Studios

Whether you're an artist, writer, or in need of a creative space, prefab studios provide a serene and dedicated environment for your work.

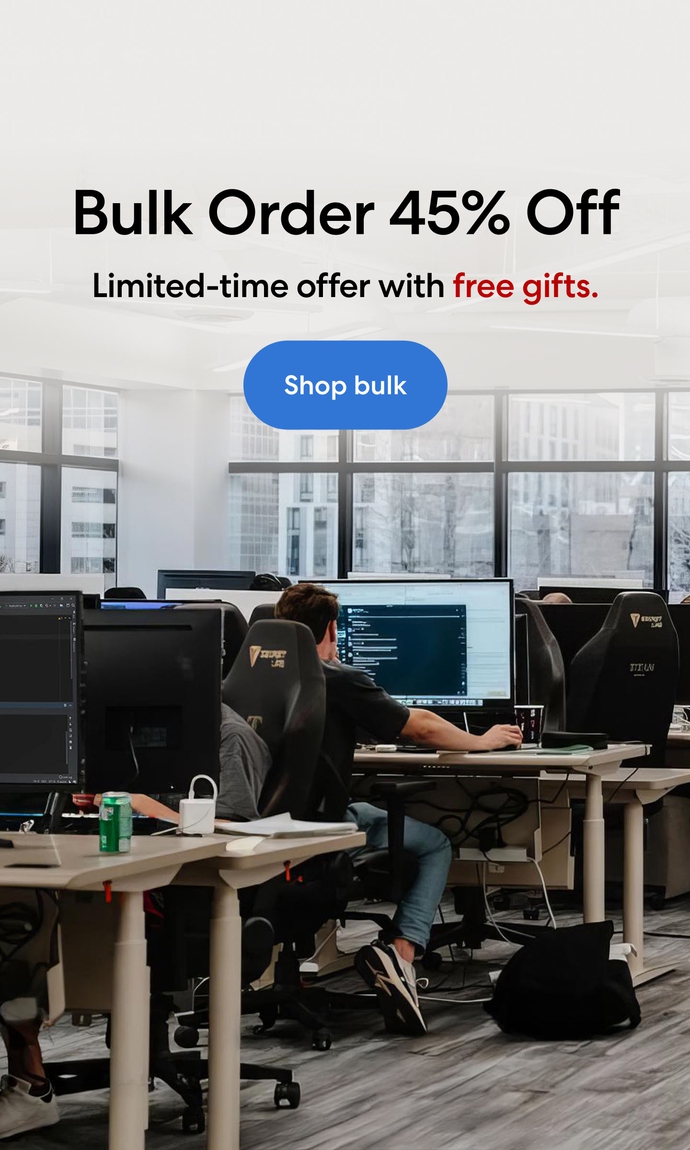

Backyard Workrooms

As more people embrace remote work, prefab workrooms are becoming popular. They offer a quiet and productive office space steps away from home. We'll leave more tips for decorating such units in another section below.

The Best States for Building Prefab Structures

Suppose you're considering investing in a prefab building. In that case, knowing which places in the US are most favorable for such construction is essential. The three best states for tiny homes include:

- Florida

- Utah

- North Carolina

Oregon, for example, also has a thriving prefab building industry. Other states that recently embraced prefab construction include California, Texas, Washington, and Colorado. Regulations vary from state to state, so research and compliance are crucial.

A Detailed Overview of the Benefits of Prefabricated Buildings

This innovative construction method is famous for its speed, cost-efficiency, and versatility. It's an attractive option many new and young homeowners are considering.

Fully or Partially Assembled

The ADU design can be fully or partially assembled off-site. Workers make fully assembled units in a factory. The process includes all interior finishes.

Partially assembled units may comprise single parts like walls, floors, or roofing panels. Builders assemble them later on-site.

Fast Construction

One of the primary advantages of prefabricated buildings is their speed of construction. Since many components are typically made together in a controlled environment, the assembly process is faster than traditional on-site construction. This streamlined process is essential in time-sensitive projects.

Transferred to Site

As highlighted above, workers transport prefabricated components to the construction site once they are completed.

This minimizes exposure to unfavorable weather conditions and reduces on-site labor requirements. It also allows for precise scheduling, resulting in more predictable construction timelines.

Reusability

Another noteworthy feature of prefabricated buildings is their reusability. Many prefab units are easily disassembled and moved to a different location. This flexibility can benefit temporary structures like construction site offices or event venues.

Many prefabricated units use sustainable and eco-friendly materials, making them responsible choices.

Efficiency and Convenience

Prefab construction offers efficiency and convenience in many ways. The controlled factory environment ensures consistent quality, reduces material waste, and minimizes construction-related disruptions in the surrounding area.

Additionally, the modular nature of a prefabricated building allows for easy expansion as needs change.

The streamlined construction process of prefabricated structures often translates into cost savings in labor and materials.

Versatile Applications

Prefab structures have many uses. This makes them a versatile choice for different industries and purposes. Some common applications include:

- Camps: Prefabricated structures are common in remote locations for temporary housing. You will find them in mining camps, military bases, and research outposts.

- Office Spaces: Many businesses opt for prefabricated office buildings to create extra workspace.

- Airbnb: Hosts use cabins, cottages, and tiny houses to provide cozy accommodation choices.

- Housing: Some homeowners opt for prefabricated homes for their efficiency and the ability to customize them, compared to traditional housing.

- Emergency Shelters: Prefabricated shelters provide a rapid and reliable solution for displaced victims. You will find such units in disaster-stricken areas.

- Educational Facilities: Schools and colleges often use prefab classrooms to house student populations.

Residential Efficiency

Prefabricated homes come with optimized designs that are functional. These designs have efficiency and sustainability in mind.

The Potential Risks and Challenges of Prefabricated Construction

While prefabricated building construction offers many advantages, like any other manufacturing method, it comes with its own set of risks and challenges.

Not a Universal Solution

Prefabrication may not be suitable for all types of construction projects. Complex and customized structures may face design limitations.

Also, prefabricated buildings may have limited aesthetic options compared to traditional construction.

Initial Investment

Cost savings are a potential benefit of such units. Still, there's an initial investment required for factory setup and tooling. This investment can be at risk if a project doesn't proceed as planned.

Quality Control

Prefabricated construction emphasizes quality control. However, the reliability of the final product depends on the manufacturer's adherence to regulations. There can be variations in quality if the process is not monitored.

Sealing and Waterproofing

Ensuring proper sealing and waterproofing in prefabricated structures can be challenging. Inadequate sealing can lead to leakages over time.

Transportation Expenses

Shipping costs for large units can be expensive. This is true if the destination is far from the manufacturing facility.

There can also be delays in the production process, especially if there are unforeseen issues in the factory. These setbacks can impact project timelines.

Building Codes and Regulations

Compliance with local building codes and regulations can be complex for prefabricated buildings. They must meet factory and on-site construction standards.

The Seven Different Types of Prefabricated Structures

Prefabricated construction involves a wide range of building types. Each serves specific purposes and meets unique requirements.

Quonset Huts

Such huts are iconic prefabricated structures known for their distinctive curved, dome-shaped design.

They are typically made of steel alloys and have wide sections of galvanized steel. Quonset huts are popular for their durability and versatility. Businesses use them for different purposes. This includes military barracks, storage facilities, and even housing.

Fiberglass Units

Fiberglass prefab structures are famous for outdoor use due to their lightweight yet durable nature.

These units feature fiberglass wall cladding. They provide excellent heat, cold, and wind resistance.

The panels are usually mounted on a plastic composite base. This enhances their tensile strength and durability. Fiberglass units are popular as garden sheds, greenhouses, and outdoor storage.

Temporary Prefab Units

You can install temporary prefab units where quick deployment and flexibility are paramount. Businesses make them from materials like steel, aluminum, and PVC.

These units are often used in emergencies, such as disaster relief efforts or temporary housing for displaced people. They provide basic shelter and may include features for temperature control to ensure comfort.

Modular Homes

Such homes are prefabricated residential structures built in sections or modules in a factory. They are transported to the construction site and assembled on a foundation.

Modular homes can range from basic, single-story structures to elaborate multi-story houses. They offer homeowners the advantages of cost efficiency and reduced construction time.

Panelized Buildings

Such buildings use pre-made wall panels, roof trusses, and floor systems. Workers manufacture the pieces in a factory and then transport them to the construction site for assembly.

Panelized construction offers a balance between traditional stick-built construction and fully modular construction. It allows for design flexibility while benefiting from factory production's efficiency.

Prefabricated Commercial Buildings

Prefabricated construction is not limited to residential structures. Many commercial buildings, such as offices, retail spaces, and warehouses, also use such components. You can customize them to meet specific business needs. They also offer cost and speed advantages.

Container Homes

You can also make a prefabricated building using repurposed shipping containers. The containers are modified to create livable spaces. Manufacturers stack many containers to create larger homes.

Container homes have gained popularity for their eco-friendliness and affordability. They are often used as alternative housing solutions and can be customized to meet various design preferences.

How to Decorate a Prefabricated Building Unit without Breaking the Bank?

Decorating a new space doesn't have to be an all-or-nothing task. Start with the essentials and add accessories as your budget allows.

Over time, your prefabricated building unit will become a comfortable and inviting area. It will reflect your style and personality.

Paint with Purpose

A fresh coat of paint can transform any space. Choose light, neutral colors to make the room feel larger and more open. Paint an accent wall with a bolder color to add visual interest without the cost of coloring the entire room.

DIY Artwork

Create your artwork or wall decorations. You don't need to be an artist – simple, abstract pieces or framed photographs can be striking. Look for inexpensive frames at thrift stores or discount shops.

Secondhand Furniture

Thrift stores, garage sales, and online marketplaces have affordable furniture in good condition. Look for sturdy, well-maintained pieces that you can clean or refurbish.

Repurpose and Upcycle

Get creative with what you have. Repurpose old furniture or decor items to fit your new space. A coat of paint or new hardware can breathe life into an old piece.

Budget-friendly Accessories

Shop for affordable accessories like throw pillows, rugs, and curtains. These items can add color and personality to your prefab unit without increasing cost.

Buy storage solutions that serve a dual purpose. They can keep your space organized and can be decorative. Floating shelves, storage ottomans, and modular units can help maximize your area.

Natural Light

Make the most of natural light. Keep windows clean and unobstructed to let in as much sunlight as possible. Natural light can make a space feel more inviting and open.

Houseplants are your new best friend. They are an affordable way to add life and vibrancy to your space. Greenery also improves air quality. Look for low-maintenance plants; you don't need a green thumb to know how to take care of succulents.

Final Words

Prefabricated building construction is a versatile and innovative approach. They can cater to a wide range of needs and preferences. Whether you're considering a cozy backyard pod or a commercial space, the benefits of this manufacturing type are clear: speed, efficiency, and quality.

The demand for efficient, adaptable, and environmentally friendly building solutions continues to rise. Prefabricated construction stands as a promising and progressive choice for the future of architecture and design.

Spread the word

.svg)

.webp)

.webp)