A Comprehensive Guide to Modular Cleanroom: All You Need to Know

If you've ever worked at a factory that employs a lot of research, you must be familiar with the concept of a cleanroom. These are dedicated rooms that act almost as a lab allowing engineers and researchers to do all sorts of things in a sterile, isolated, and clean location. However, due to such specific demands, building an entirely new cleanroom at any factory can be a considerable task, not to mention the disturbance their construction can cause to other workers in the building.

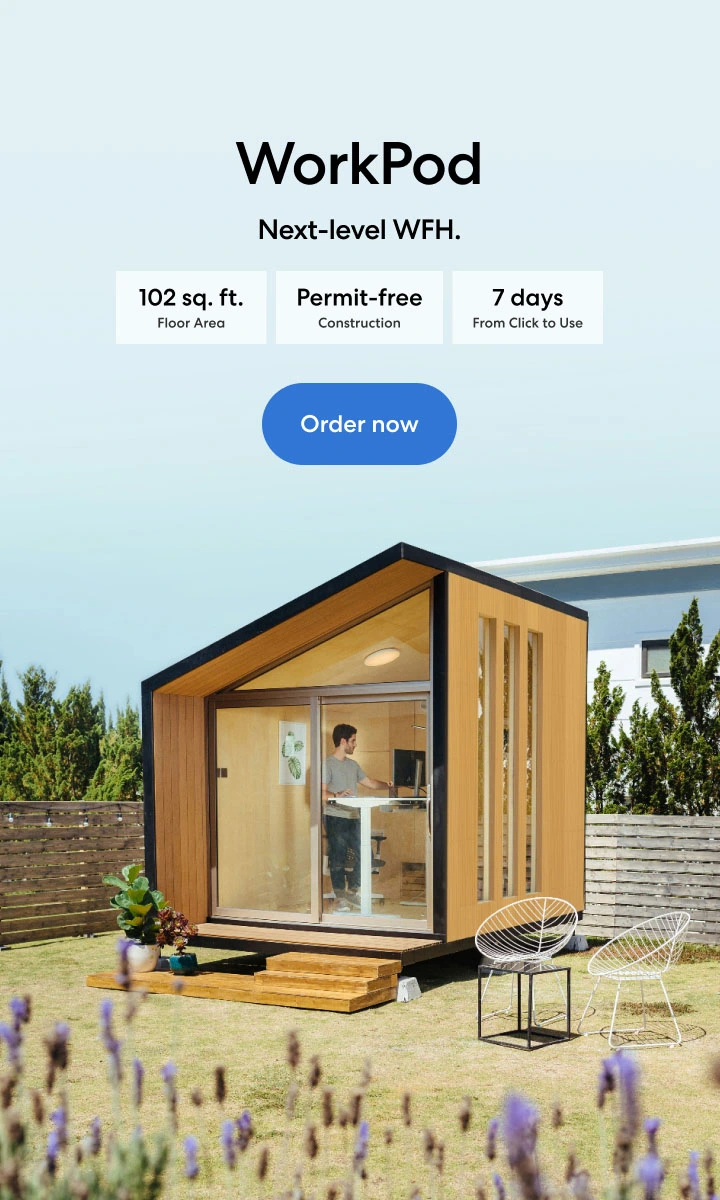

This is why many people are slowly shifting toward the use of modern, modular cleanrooms that only require the bare minimum of assemblies and can be work-ready in less than a week, thanks to their pre-fabricated nature.

That being said, a lot of people still find themselves confused in this new and exciting world of modular cleanrooms which is why n this article, we will talk about how exactly these things work, the specific reasons you might want to choose them, and the considerations you have to keep in mind when looking to get one.

How Does Modular Construction Work?

As the name suggests, modular construction consists of different modules that combine to build something. More specifically, most modular construction applications use factory-made walls, ceilings, and other building components that can then be transported to the required site and assembled by a small team.

For most modular construction projects, the parts or modules are usually already designed and have been manufactured. All the construction firm has to do is choose the correct modules and assemble them in the desired layout on site.

As you can imagine, this not only saves a lot of time and trouble, but since the parts are all made in a controlled environment, it also allows for much more consistency and fine-tuned quality, which are very important for applications like cleanroom design.

What Are Modular Cleanrooms?

Like their regular counterparts, modular cleanrooms are designated workspaces whose environment is maintained and controlled at a minute level, with things like cleanliness, temperature, humidity, and air quality being of particular interest.

This is done by using special, high-quality equipment that allows for the control of these factors, paired with a construction that allows these factors to be maintained. And while there are many possible applications for such rooms, they are mostly used in research-based industries like pharmaceuticals, biotechnology, electronics, aerospace, and medical device manufacturing for testing and developing new things.

Only, instead of having all of that limited to a large, bulky space, modular cleanrooms allow for the transportation and installation of such rooms basically anywhere that meets the design specifications. These rooms are also different from standard modular offices as their components are a lot higher quality and have to meet a lot more regulations.

Benefits of Modular Cleanrooms

As you can imagine, there are a lot of reasons you might want to get a modular cleanroom for your factory, but some of the major ones include:

Adaptability

Since the equipment and construction of these cleanrooms are modular, it is much easier to replace and upgrade modular cleanroom systems as needed, allowing companies to enjoy modern technology without extensive renovations.

Cost & Time Effectiveness

Because their components can be mass-manufactured, modular portable cleanrooms are also much more cost-effective than traditional construction methods, with some applications, like prefab ADUs being exceptionally affordable. Similarly, since the parts are already made, putting together a modular cleanroom is also much faster than other methods.

Higher Standards

One of the most desirable pros of using a modular cleanroom is the higher level of quality and standards they can meet because their parts are manufactured in a controlled environment, which is especially important for scientific applications like cleanrooms.

Temporariness

Because of their ease of assembly, these cleanrooms can be set up for short periods of time before being disassembled. They can even be transported between different sites, which makes setting up an entire modular office building much cheaper and easier.

Considerations When Getting a Modular Cleanroom

Like most modular construction projects, the design and construction process of modular cleanrooms will be quite different from regular construction and will change based on the modular cleanroom manufacturer you go with. That being said, there are a few considerations to keep in mind.

Use-case

As you can imagine, what you'll use the cleanroom for is going to determine a lot of factors, including materials, costs, and type of construction, so the first thing to consider is whether your application is on the smaller side, like a small-scale electronics firm which can make do with standard office sheds or a pharmaceutical corporation dealing with life-threatening diseases which will need more advanced modern shed construction.

This also determines the kind and level of control you will require, including the ventilation/circulation setup, temperature & humidity environmental controls, as well as things like lighting, air particulates, and filters, etc.

Standards

As with regular construction, the making of cleanrooms has to comply with local building codes. But since they are such a sensitive application, cleanrooms have to meet many other standards as well, so keep the exact standards your industry demands before looking for one.

Material & Construction

Another thing to consider is the physical construction of the shed, which can be affected by things like the location of the eventual cleanroom, whether it will be inside or outside, and the amount of stuff you will be putting inside of it. This is why we recommend that you have a rough idea of the kind of heavy lifting your modular cleanroom will be doing. That will show whether you are okay with simple wood sheds or need something stronger, like the more popular sheet steel construction.

Budget

And finally, the most self-explanatory one is the budget. And while these things are definitely not cheap, with the right decisions, you can find many cheap options, including affordable prefab homes that can be modified into the modular cleanroom of your dreams.

Bottom Line

All in all, while modular cleanrooms are far from a simple or easy-to-buy thing, as long as you follow the information we've told you today, you should be able to get yourself an advanced, high-quality, and industry-standard cleanroom to improve your industry without any major hurdles.

And that covers our guide on modular cleanrooms. We hope you found the guide helpful, and if you did, remember to share this with your friends. With that, stay curious, and thanks for reading.

.svg)